Your Cart is Empty

Sale

Build an Enviro Wooden Balsawood Surfboard with Mark Riley at Miranda

$379.00 - $450.00$400.00

The group of 2 will be customised to the type of board you want to build. It will be hands on getting dusty on any day that suits the students. Mark will take you step by step in building your own solid or foam core wood board that can be glassed and surfed or hung on the wall just like in the 50s and 60s. All equipment will be supplied in a kit form and all tools necessary will be supplied in a safe and clean environment. The whole process is environmentally friendly and boards will be built to your requirements and your ability.

You can build your size board - the recommended shapes are fishes, mini mals, and guns from 5 feet to 9 feet. If you don't want to build a board you can experience a build alongside Mark in his workshop.

The boards that you will build are not hollow with a frame- there are no restrictions to YOUR shape. This is the way boards were built in the 50s and 60s. These last a lifetime when they are glassed properly (no cheap wood stains or oils or clear varnishes here that need maintenance).

You will learn to use a band saw, circular saw, electric planer, and electric sanders and to design and draw your shape, all under the supervision of Mark.

You can choose your preferred stringer layout from no stringers to 5 stringers in different arrangements (kit comes with 1 stringer, extra $50 per stringer).

Photos will be taken of the students during the build and sent to them.

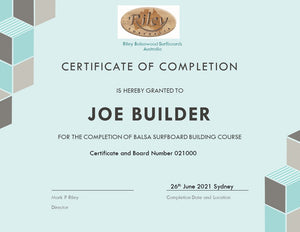

A certificate will be presented on completion.

This is a great escape and relaxation after a long working week. Normally the guys are sad when they have finished the course and want to help and volunteer to help out building other boards. They all want to learn more and meet more like-minded people.

We will meet once a month to try out your creation at Fluro Fridays at Wanda Beach. Send a message to ask when the next one is on. Or visit Fluro Surfing on Facebook - https://www.facebook.com/groups/272540596696317

Kits are purchased separately - you could also make a tide clock or short board or fish or mini mal or longboard in solid balsa. Purchase here – https://balsawoodsurfboardsriley.com/collections/shaping-accessories/products/balsa-surfboard-shaping-sets.

Time-lapse video of Mark building a balsawood surfboard in PNG

Balsa surfboard shaping set or kit $400 - $750 (this is subject to change) plus the cost of the course. Glassing is extra.

Help Mark build a balsa board. Just pay for the class (no need to buy the wood) and work along side Mark to build a custom order for Riley Balsawood Surfboards.

Click here to see a video of the classes.

Have you ever wanted to build a wood board like Cody from Surfs Up Movie?

So sign up now!

Extra 20% surcharge for Saturdays.

If you build a second board a 10% discount will apply.

All accessories like board covers will apply a 10% discount.

You can then take your board away for glassing or come and see it being glassed one on one with Mark at his glassing bay (this is extra).

A wooden board needs to be glassed and polished or a matt finish is cheaper to have it last a lifetime.

Course Outline:

The process below is building a solid board or a foam core balsa board.

Session 1

11am to 11.30am – Introductory talk

11.30am to 12pm – Hand over of kits

12pm to 12.30pm – Layout of wood or foam and cutting wood and foam with the band saw

12.30pm to 1.30pm – Glue up blank or shape foam

1.30pm to 2.30pm – Remove clamps or glue on the balsa sheet to the bottom

2.30pm to 3.30pm – Draw plan shape or shape foam deck

3.30pm to 5pm – Cut out plan shape with a circular saw or glue on balsa sheet to the deck

Session 2

11am to 12pm – Shaping bottom with an electric planer or cut plan shape to balsa sandwich

12am to 1pm – Shaping deck with an electric planer or glue on balsa bands/rails

1pm to 2pm – Sanding bottom, Shaping rails with a block plane

2pm to 3pm – Sanding rails with sanding blocks

3pm to 5pm - Finish sanding board talk about fins and glassing

Learning Outcomes:

To have an understanding of balsawood and the environment and how mass-produced surfboards are impacting the environment. How to use power and hand tools to achieve a great-looking wood board and one you can surf on or hang on the wall.

What to bring:

- Covered comfortable shoes.

- Old clothes because you may get glue or dust on them

- Bottle of water

- Purchase a Balsa surfboard shaping set or kit $400 - $750 (this is subject to change)

The Tutor:

‘I have been building balsawood surfboards since 1996. I have been importing balsa from Ecuador and Papua New Guinea for over 20 years. I send boards all over the world and can be seen in the surf, in restaurants, offices and showrooms. I am very meticulous with the finish and am a perfectionist when building wood boards. I care about the environment and want to change the physic of mass produced toxic board buying communities to a hand made custom long lasting wood board community by teaching how to build a sustainable balsawood surfboard one board at a time.’ Mark

Other Information:

Bring a face mask

By ordering and paying for this course online you are accepting this waiver.

- By accepting this waiver, you are accepting in its entirety the following conditions.

I agree that during the ''surfboard making course,” I waive any claims that may arise about my personal or others' injury, damage to property, death or any other claims relating to my participation in the course.

Whilst there might be certain risks in partaking in the course, I acknowledge I have received all the necessary instructions and safety gear to safely conduct the course without any safety incidents to myself, others or property.

I am a mature adult and am very aware of all the risks and requirements to safely navigate my way through the course.

Contact Mark via email to let him know your suitable dates to make a start - mark@riley.com.au