B

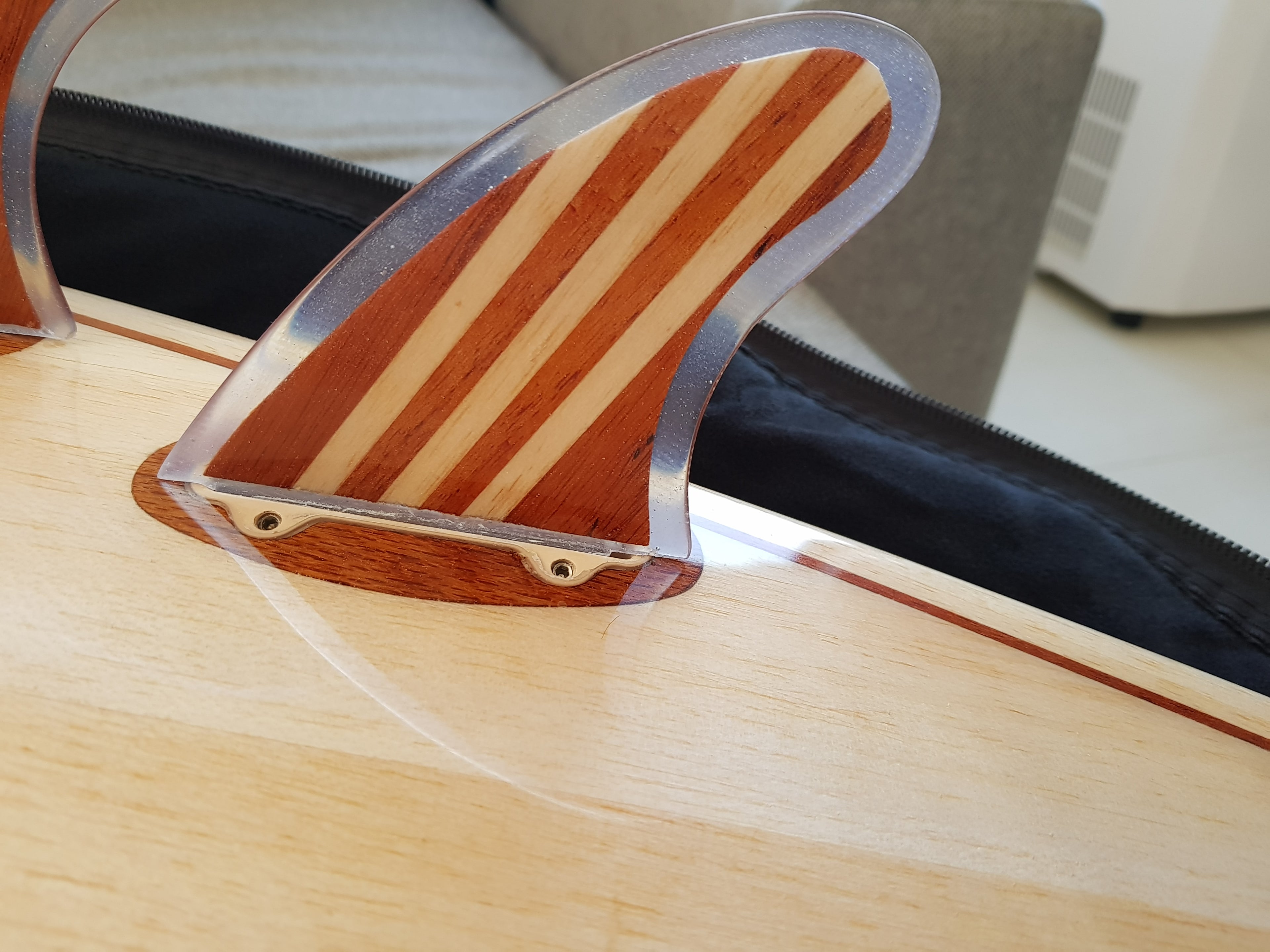

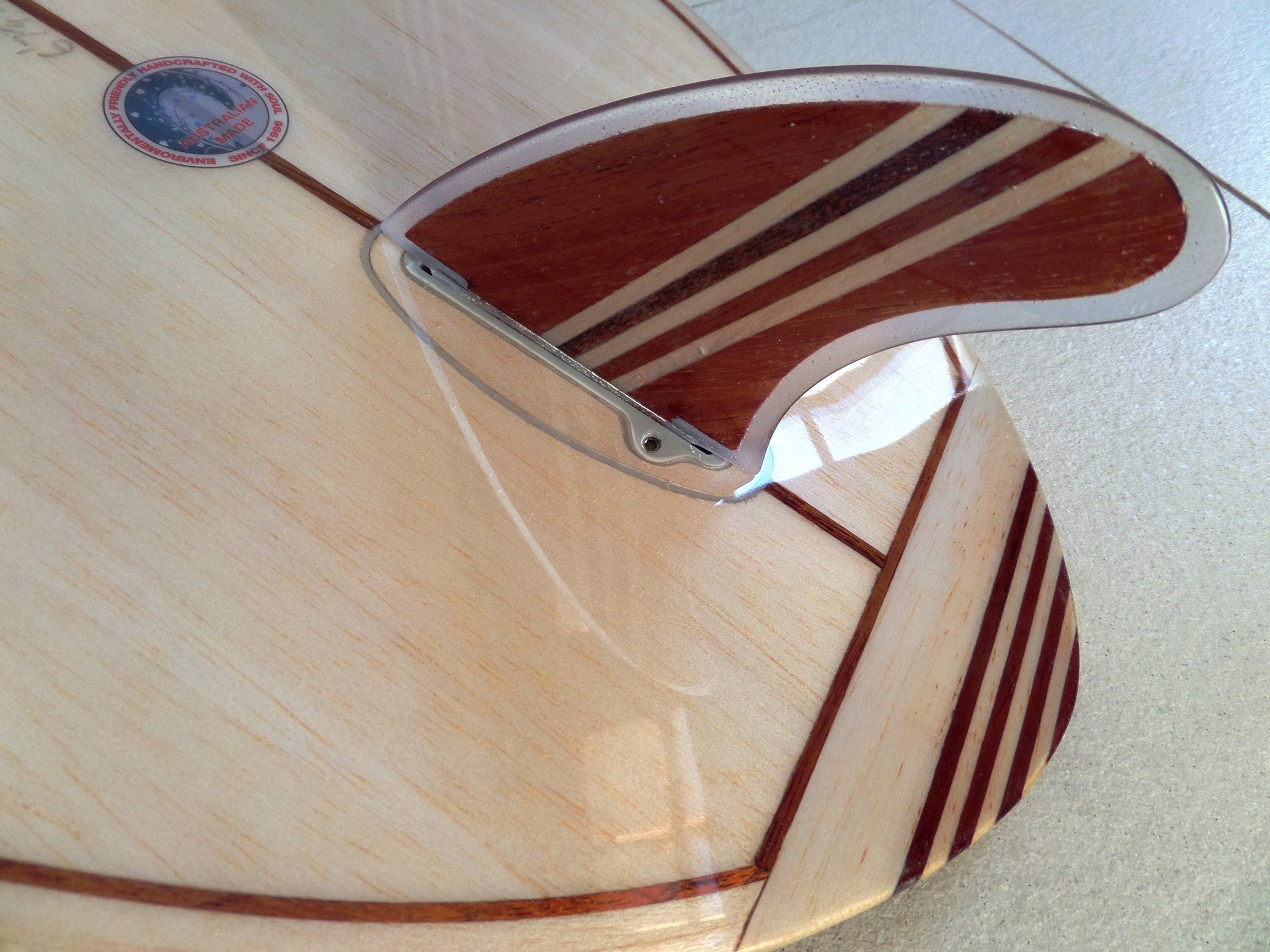

Brian Hi mark it's Brian here from Wollongong. Finished the board got it glasses locally and am absolutely stoked with how it came out. Can't wait to get it in the water! Every thing I needed was in the kit and your DVD was so helpful. Balsa quality is awesome and the colour of the board is amazing. Gearbox fin system is so sweet. Thanks heaps for your input and help. 👍🏽👍🏽

Brian